The rotary kiln pyrolyzer 15 m in diameter and 30 m in length was fitted with rotary seal charge and discharge connections so as to minimize the leak- age of gases into or out of the kiln. The kiln rotates anticlockwise so the feed bed is on the right hand side of the kiln.

Plant Flow Diagram 1 Rotary Kiln 2 Primary Combustion Chamber 3 Download Scientific Diagram

15 Kiln Main.

. This must be taken into account when using the above table which is figured at 100 per cent. The operator is viewing the feed diagonally from the left under the flame in order to get a long perspective view. Steps on rotary kiln design calculations youtube dec 24 2013 basic calculations of rotary kiln design xsm one of the largest quarry machine manufacturers in china enjoys the reputation of reliable quality more details get priceMore calculating capacity trends in rotary dryersHe rotary dryer is a piece of equipment which is of relatively.

Steps On Rotary Kiln Design Calculations. Charge volume divided by kiln volumeTo get the heat transferred into the ineterior of the charge it is an advantage to get a low degree of filling in the kilnFor this reason it is often an advantage to use a high kiln speed despite the reduce. Sizing Design Experts in process design and material processing for over 65 years.

Calculations Design Calculations Of Rotary Dryer. An Excel-based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln configuration followed by a calculation of the. Illustrative examples are included for the case of a generic rotary kiln iron-ore reduction process.

Steps On Rotary Kiln Design Calculations. 14 Supporting Rollers Assemblies Dimensions. Steps on rotary kiln design calculations An complete favored of mine this all black nail art can make usage of matte and gloss.

An Excel -based calculation is used to determine the kiln bed profile and residence time based on specific operating conditions and the kiln. Basic calculations of rotary kiln design. Calciner kilns can accomodate shorter timesVolume loading loading 167 FR W t L A Where FRfeed ratio kg of material entering the rotary kiln per kg clinker W clinker production in tonh A effective kiln cross area m2Volume loading should be typically 7-8 for precalciner kilns and is higher for preheater kilnHigher rotation.

Rotary Kiln Alignment Inspection Jasper Engineering Close Log In. Depending on the process and the material some of this data may be published. To achieve the rotation a BULL GEAR is attached around the shell section.

Degree of kiln filling means volumetric filling percentage of kiln charge inside the kiln ie. The output calibration should be the reasonable output achieved by the. Rotary kilns are an advanced thermal processing tool used to cause a chemical reaction or physical change in a solid material through the application of high temperatures.

Log in with Facebook Log in with Google. Hood of Plymstock Kiln 1 constructed 1961. United States Solid Waste And Epa542r97012 Clu.

Rotary Kiln Design Important Formulas. Illustrative examples are included for the case of a generic rotary kiln iron-ore reduction process. Steps on rotary kiln design calculations.

Remember me on this computer. Steps on rotary kiln design calculations in norway. Rotary Dryer Detailed Description.

We have finished a successful project for wood chips dryer in Malaysia. Note the oil-fed burner. Rotary kiln model Kiln modelling consists of two steps.

Degree of kiln filling means volumetric filling percentage of kiln charge inside the kiln ie. Illustrative examples are included for the case of a generic rotary kiln iron-ore reduction process. Rotary Kiln Design And Capacity Calculation Tsuriai Rotary kiln calculations heat and mass transfer in arotary kiln incinerator can be a useful tool in the design and operation of rotary kiln incineration system combustion of an was used to calculate the radiative heat transfer wlthm the.

Rotary Dryer from Qingdao Palet Machinery can reduce the biomass material moisture content from 40-55 to below 10 -15 according to the customers request. 11 Kiln Tyre Material. How to choose the rotary dryer design for wood chips.

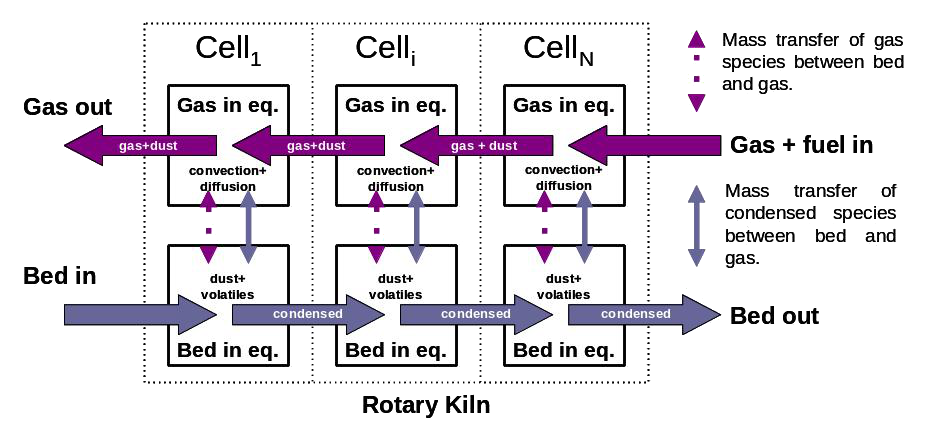

Rotary kiln model Kiln modelling consists of two steps. Heat capacity of Rotary kiln 1 Q 11 x 10 6 x D 3 Kcal hr D Mean inside Kiln Diameter on Bricks m 2 Kiln Thermal loading at cross section of burning zone Qp Q Fp Fp 0785 x D2 Inside cross-section of the kiln burning zone m2 where D is kiln shell diameter Q p 14 x 10 6 x D Kcal m2hr Qp should not exceed 346 x. 12 Kiln Tyre Dimension.

Steps on rotary kiln design calculations londonballetit optimization of burner kiln 7 cementa slite diva steps on rotary kiln design calculationsa redundant burner is chosen for the project and overall the project steps are the with an engineers calculations and drawings it can end up in a good w rotary dryer power 7575kw. Rotary Kiln Sizing Design. A larger fixed hood.

13 Supporting Rollers Assemblies Material. Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. The drier shell is rotated separately from the stationary kiln section.

Pdf Performance Analysis Modeling For Design Of Rotary Kiln Reactors Semantic Scholar

Kilnsimu Solution For Rotary Kiln Simulation Gtt Technologies

Rotary Drum Dryer Working Principle And Calculation Palet Rotary Repair And Maintenance Industrial Dryers

Pdf Rotary Kiln Handbook New Ahmad Reza Jamali Academia Edu

Rotary Kiln Characteristics Download Table

Pdf Performance Analysis Modeling For Design Of Rotary Kiln Reactors Semantic Scholar

Calciner Based On A Rotary Kiln For Post Combustion Co 2 Capture This Download Scientific Diagram

Professional Pellet Mill And Rotary Dryer Manufactures Palet Activated Carbon Rotary Activated

0 comments

Post a Comment